Case studies

Specifications

: 6,3 kV; 1500 A

Delivery date

: 27.07.2022

Destination

: Česká republika

I want similar solution

Challenge

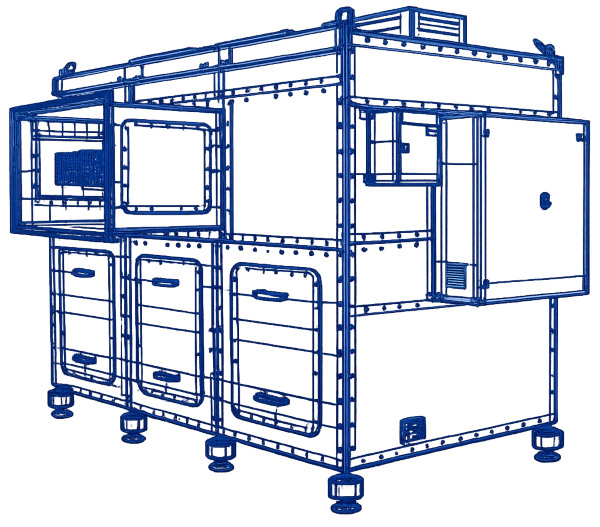

Zařízení bylo navrženo jako funkční pokračování svorkové skříně generátoru TG3 a tvoří součást širšího celku vyvedení výkonu generátoru včetně vazby na generátorový vypínač (GCB) a uzemňovací systém. Projekt neřešil pouze dodávku samotné skříně, ale kompletní inženýrské a konstrukční řešení včetně návazností na další technologie.

The Customer Placed Emphasis On:

- full functional continuity with the generator MTB,

- a clearly defined turnkey scope of supply,

- a unified standard of components and wiring,

- easy on-site assembly and installation.

The scope of the assignment particularly included:

- engineering design of the structure,

- manufacturing of load-bearing structures including surface treatment,

- cable connection contacts designed using bent copper busbars,

- complete supply of installation material (bolts, coatings, minor components),

- a terminal box – either custom-made or standardized – equipped with Siemens / OEZ components,

- wiring of interconnections between the GCB and the terminal box,

- integration of surge arresters – following technical evaluation, relocation from the MTB directly onto the GCB structure,

- bolted grounding points for a portable grounding set,

- a grounding busbar included in the scope of supply,

- design and delivery of a protective cage (fencing) for the GCB in galvanized finish.

IVEP Solution

IVEP provided:

- complete engineering design of the equipment and its integration into the generator assembly,

- manufacturing of the combined terminal box MTB + N, including structural components,

- supply and wiring of the terminal box in a unified standard consistent with other MTBs,

- design of connection busbars and grounding points with a focus on operator safety,

- coordination of changes during the project (relocation of surge arresters to the GCB) without impact on documentation or delivery schedule,

- design and delivery of the GCB protective cage as a separate yet functionally integrated unit.

The entire solution was designed to be clear in layout, safe, and easy to install at the installation site.

Result

- Fully functional and compact MV solution integrated with generator TG3

- Clearly defined interfaces between the MTB, GCB, and grounding system

- Simplified installation and future maintenance

- Flexible response to changes in requirements during the project

- A unified technical standard across the entire system

IVEP Added Value

This project demonstrates IVEP’s ability to:

- deliver not only equipment, but an entire functional subsystem,

- handle detailed engineering coordination across multiple technologies,

- respond flexibly to design changes without negative impact on the project,

- maintain technical integrity and safety even in seemingly “simple” terminal box solutions.