Challenge

In the foundry project in Poland, it was necessary to design a high-voltage switchgear capable of handling high currents at 36 kV while also adapting to the limited installation space of the facility. The solution had to be clear in layout, easily serviceable, and operationally safe in a demanding industrial environment.

Our solution

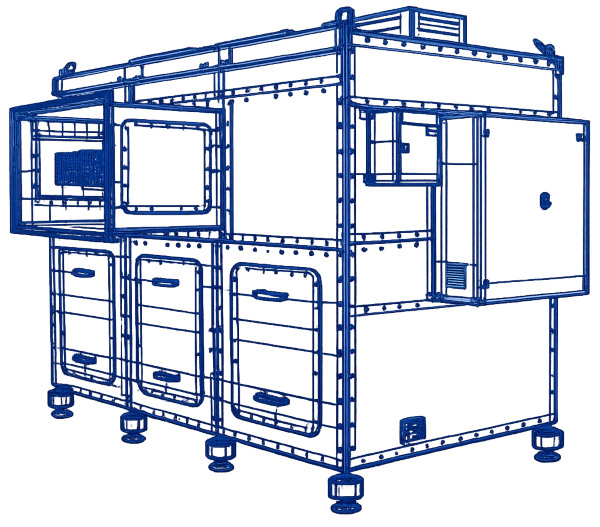

IVEP supplied a steel, air-insulated high-voltage MVSI-CB switchgear, designed as a segmented switchgear cabinet with two separate sections, arranged on two levels.

This concept enabled a clear separation of the incoming and outgoing parts of the distribution system and optimized the use of space within the technological hall.

Technical specification

- Rated voltage: 36 kV

- Rated current: 4,000 A

Switchgear layout

The switchgear is divided into two functional sections:

- Section A – incoming feeder (lower level)

- equipped with a disconnector

- Section B – outgoing feeder (upper level)

- equipped with a circuit breaker and a disconnector

This arrangement ensures:

- clear operator orientation,

- logical structuring of the power path,

- safe access during maintenance and service operations.

Design and construction

The switchgear is made of a steel structure and is air-insulated, providing a robust and proven solution for heavy industry. The design focuses on mechanical strength, long-term stability, and reliable operation in the demanding environment of a foundry.

Result

- Functional and well-organized high-voltage distribution solution for a foundry operation.

- Efficient use of space thanks to the two-level arrangement.

- Safe operation at high currents and a voltage level of 36 kV.

- The equipment was delivered on 15 December 2020 and successfully commissioned.

IVEP contribution

This project demonstrates IVEP’s ability to design spatially and technically well-engineered high-voltage solutions that respond not only to electrical parameters but also to plant architecture and operator ergonomics.